** Use CONTACT tab for international shipping options **

All kits are available under the “Shop” tab above.

This page contains basic operation of the ABC valve block to help you understand what is going on with your system. Description of kits available is at the bottom.

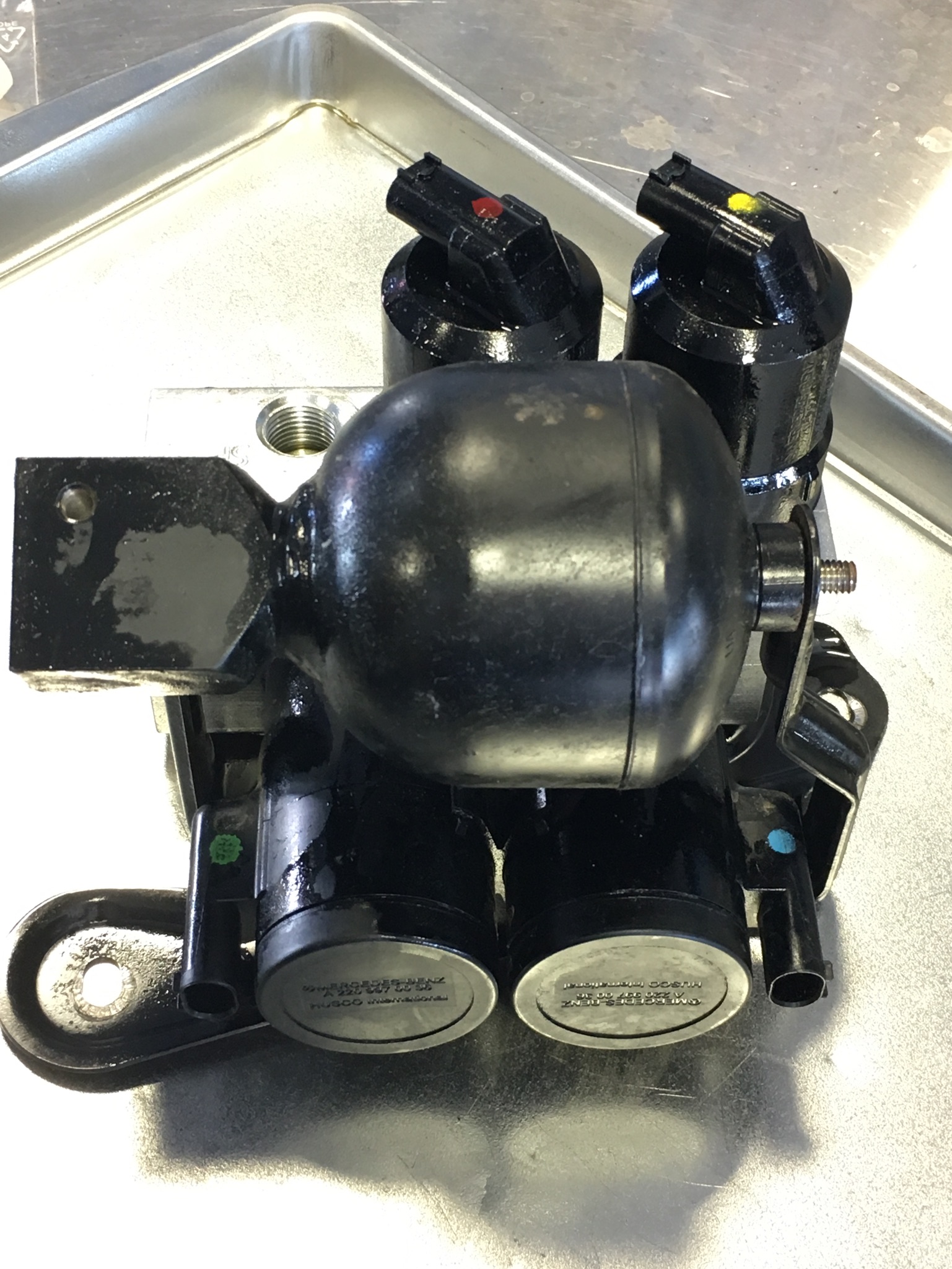

Common symptom requiring the need to replace the seals in your ABC valve block is that one or more corners of the car sag after vehicle is shut off. The problem usually occurs overnight, and sometimes in a matter of minutes. Vehicle level lowering after an extended period of time, a week or more, is perfectly normal. This is caused by one of two things, either the affected strut has an external leak, or the valve block has an internal leak. The external leak is easily identified by simply doing a visual inspection under the car at the struts. The internal leak at the valve block can be caused by dirt and debris caught in the seat of the solenoid plunger, or defective seals on the locking valves.

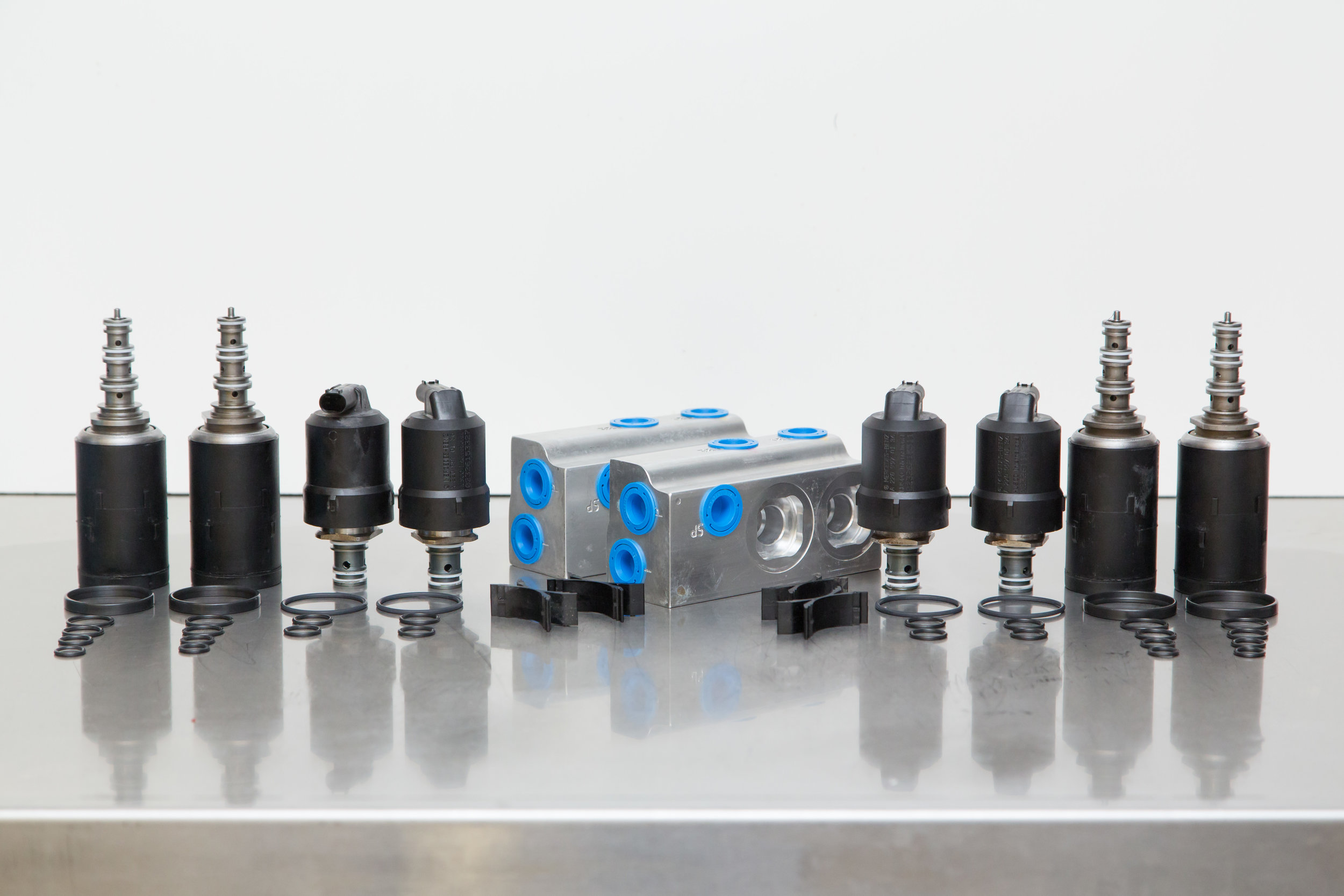

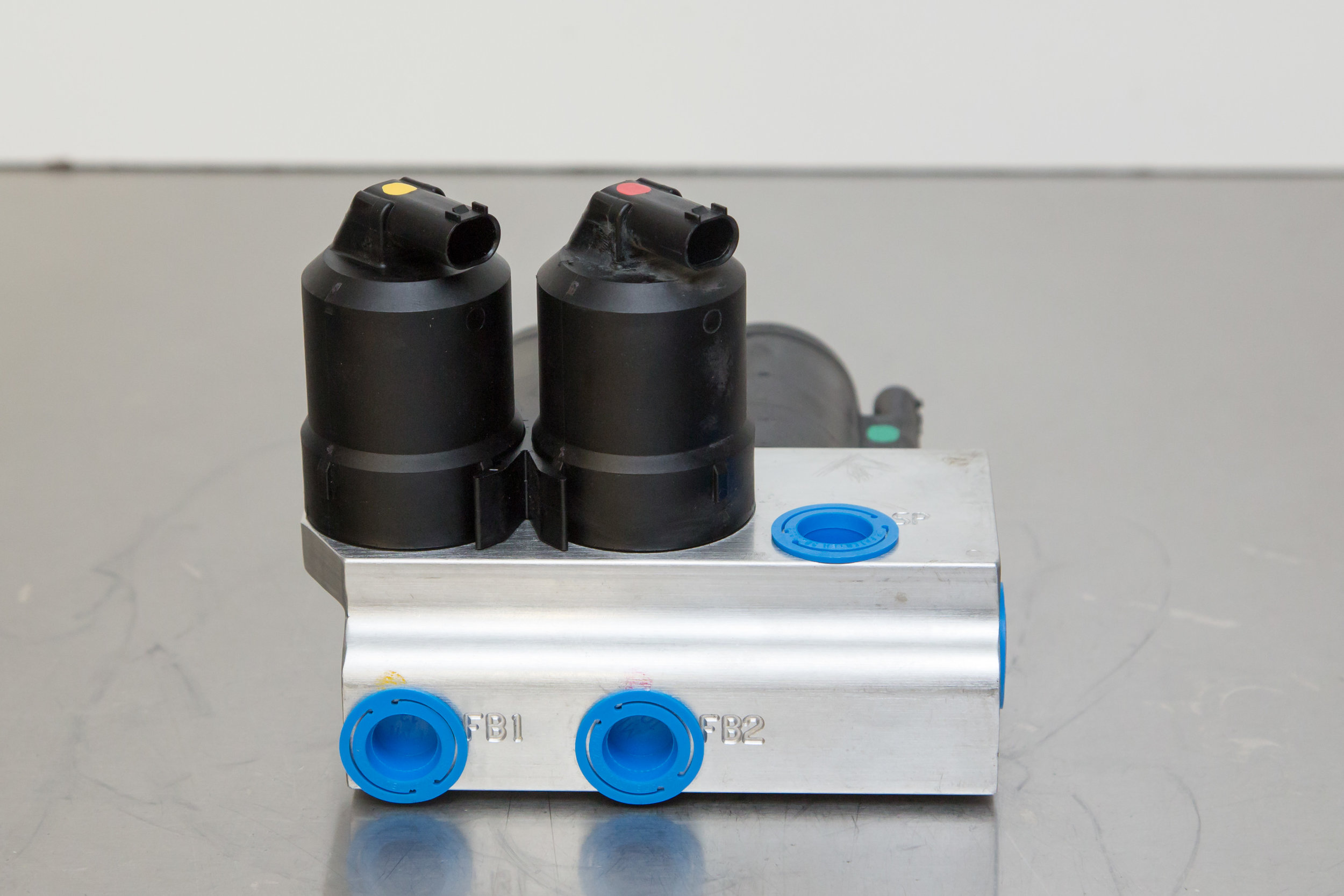

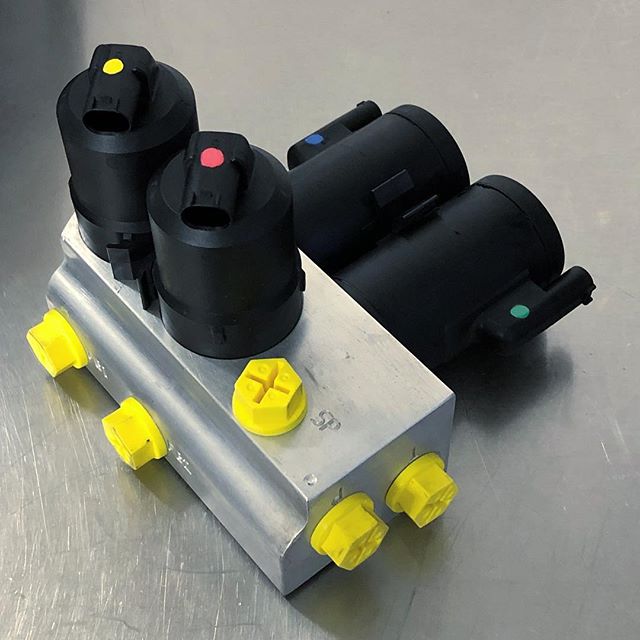

There are two valve blocks for every car, one that controls the front struts, and one that controls the rear struts. Each valve block has two locking valves and two control valves.

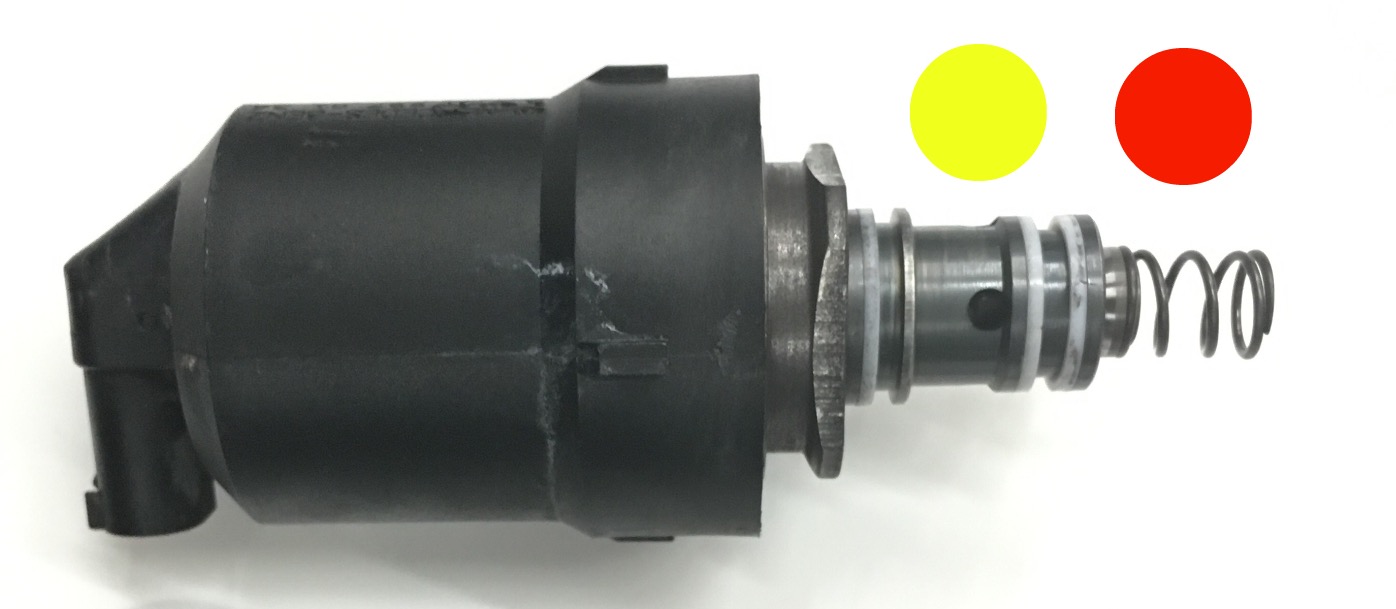

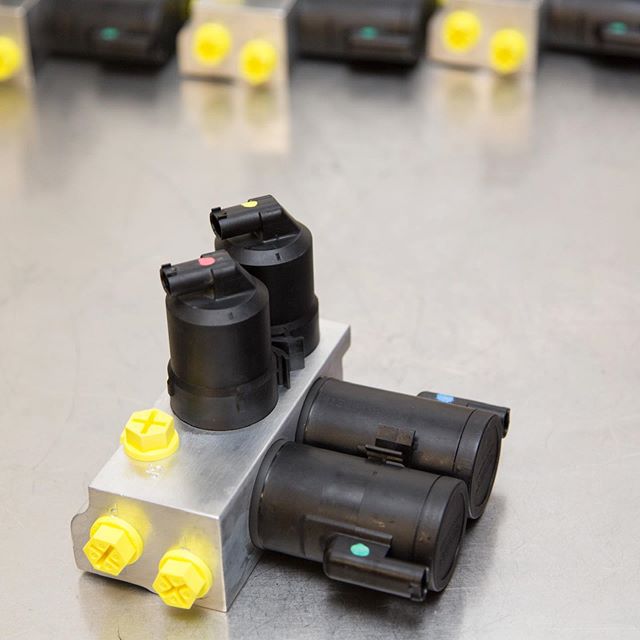

The function of the locking valve is to lock the level of the strut once the vehicle is shut off. Locking valves receive power when the car is running in order for allow fluid to move in and out of the strut. When the vehicle is shut off the control module cuts power to the locking valve and a spring keeps the solenoid plunger seated locking all fluid in the strut. If any debris or dirt is stuck in the solenoid then the plunger will not seal correctly and strut pressure will be lost resulting in that corner of the car lowering. The locking valves are marked red and yellow. The video below shows the movement of the valve when activated.

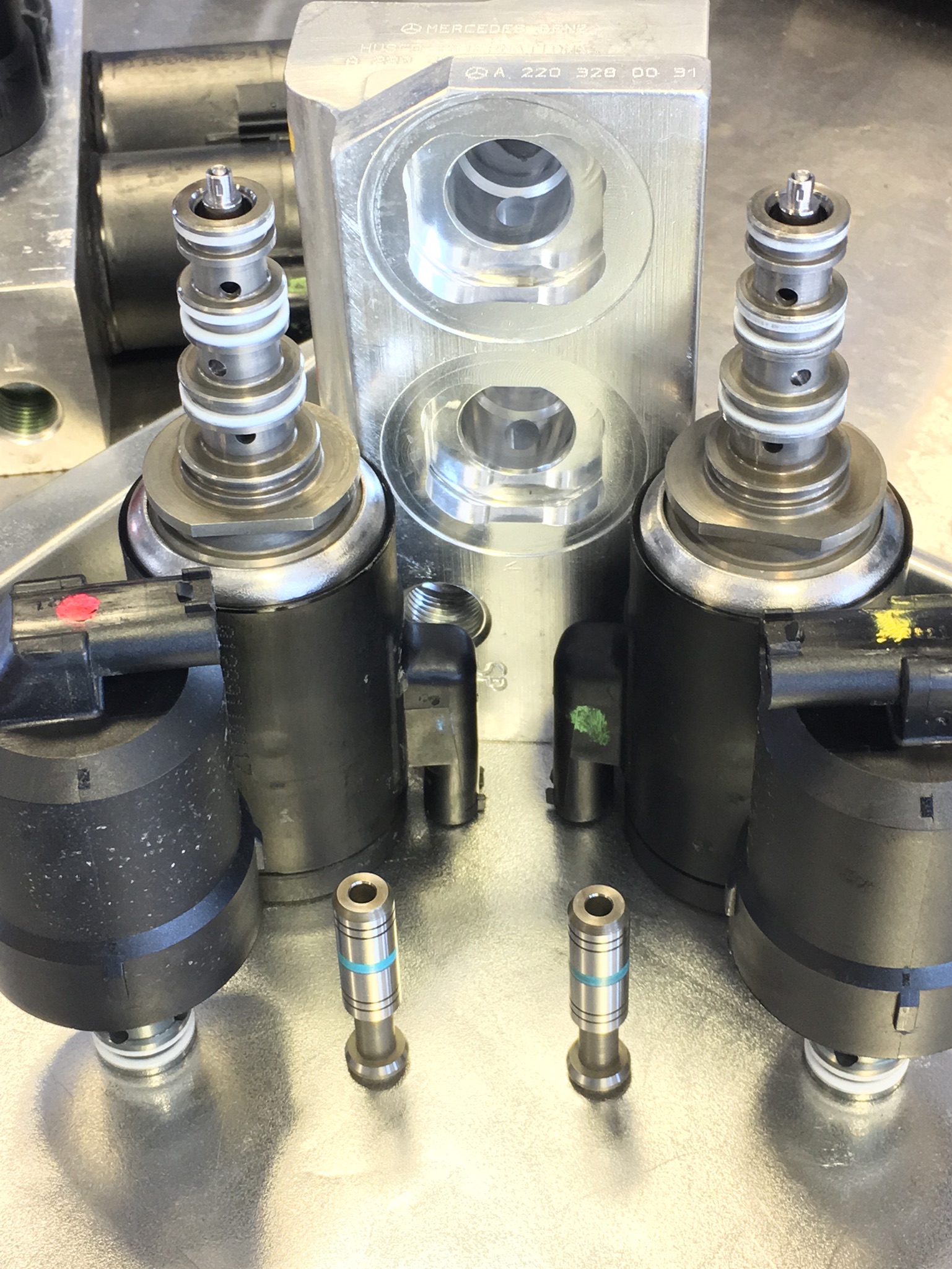

Function of the control valve is to allow fluid to go into the strut or allow fluid to come out of the strut based on what the control module is requesting. If you look at the solenoid you will see three chambers that the fluid goes through. The lower chamber is the pressure supply side, the end deepest in the valve block, on right side of next image. The center chamber goes to the strut. The other end, closest to the external portion of solenoid, is the return side. Direction of flow through solenoid is determined by the polarity of the power applied. The video below shows function of the valve in both directions and port identification.

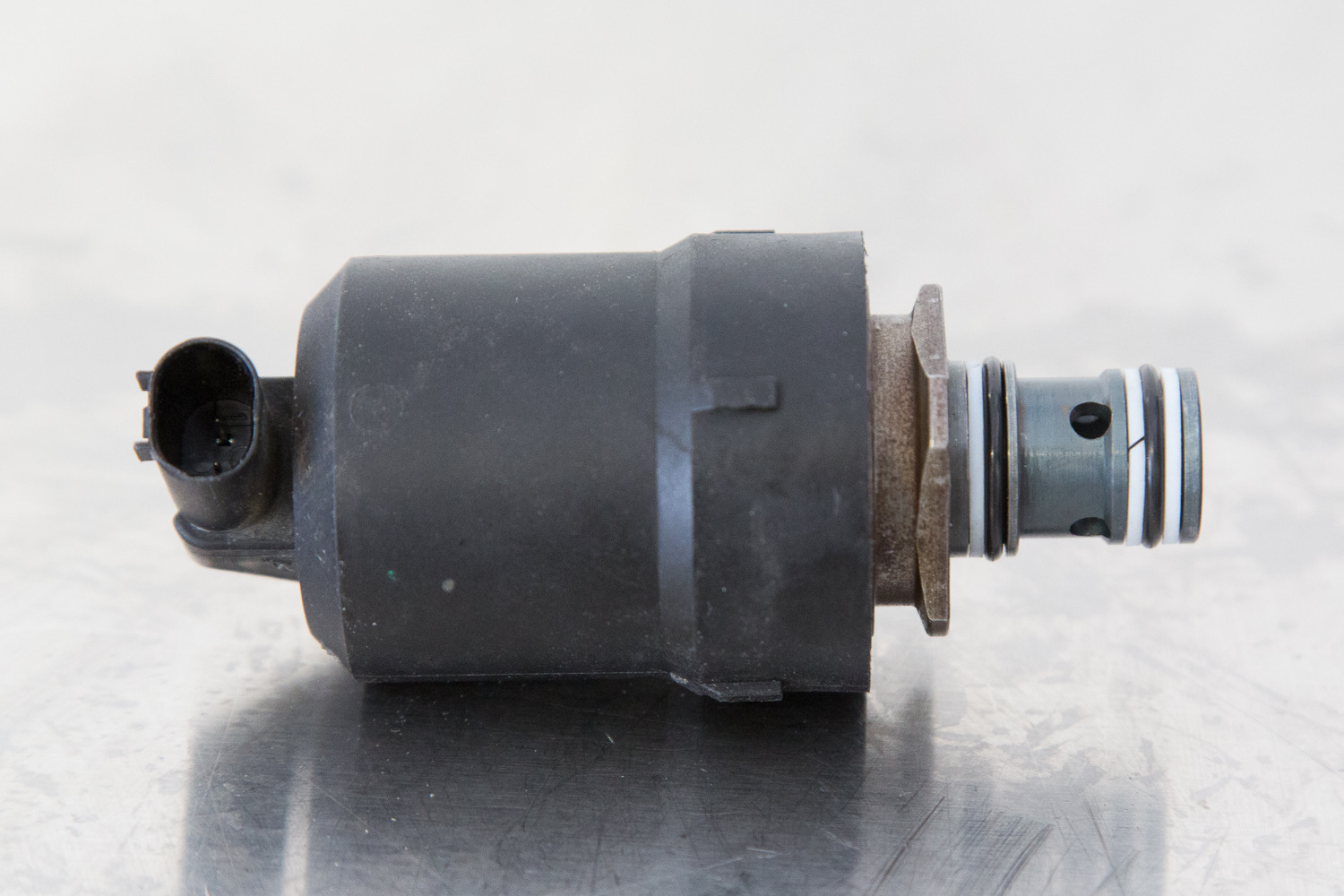

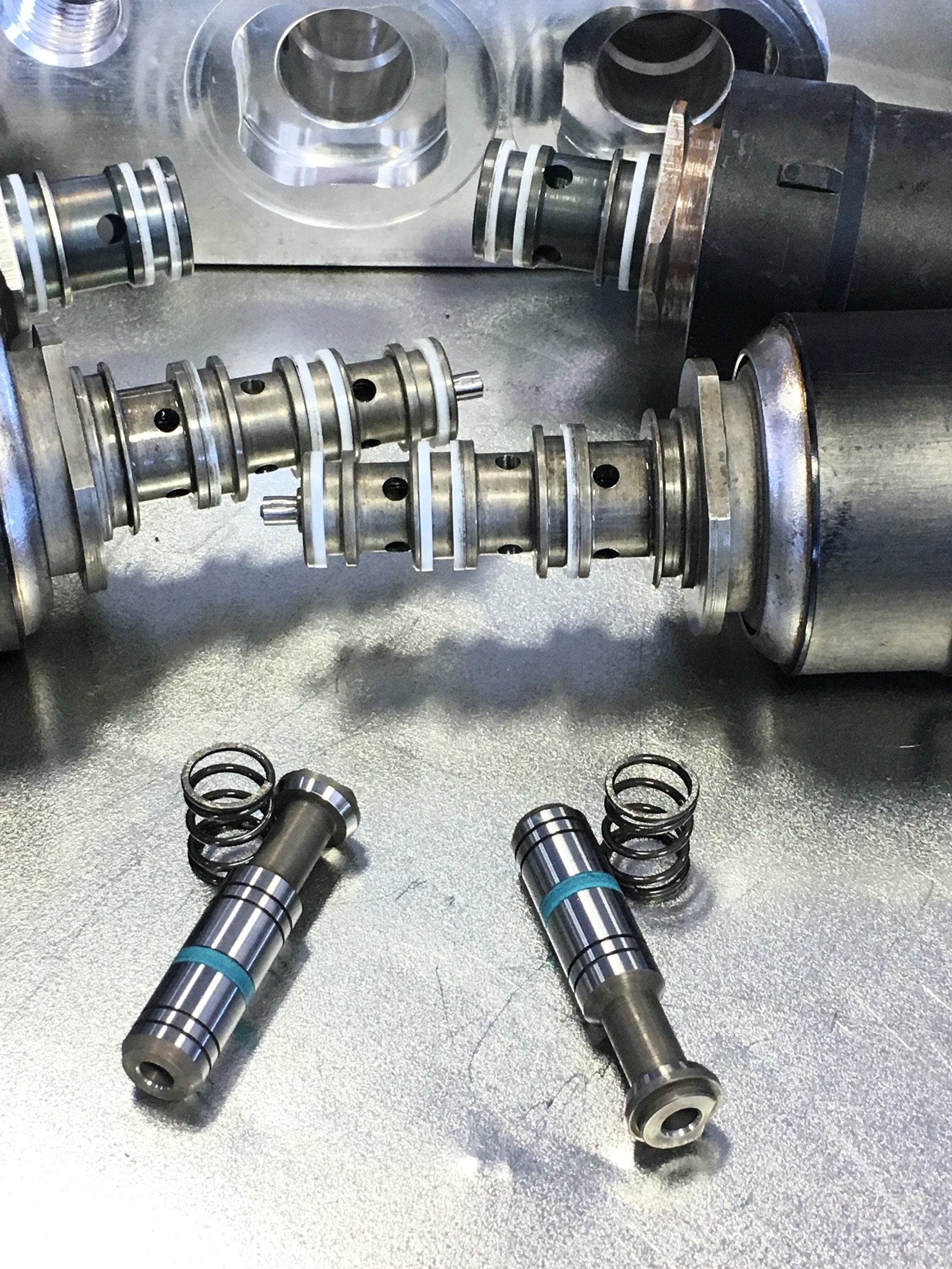

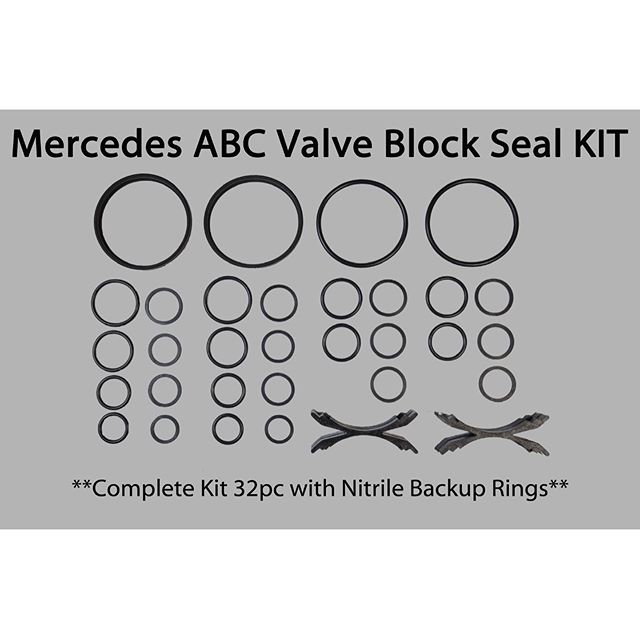

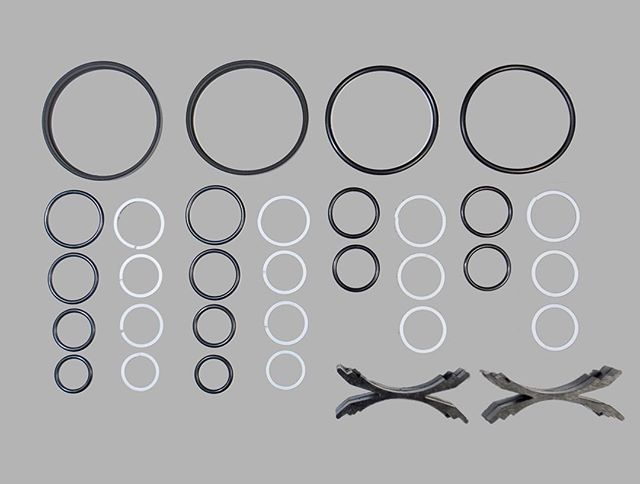

The solenoids have o-rings and back up rings. The function of the backup ring is to help maintain the shape of the o-ring under pressure and allow the o-ring to handle the high pressures of the ABC system, see below image. First generation valve blocks used teflon backup ring that rarely wears out and I would advise against replacing these unless they are physically damaged. I can't be certain of when but somewhere around mid2004-2005 the manufacturer started using nitrile back up rings. I always advise to replace the nitrile back up rings with PTFE when they are present. The complete kits I offer come with Nitrile or PTFE backup rings.

***Using the correct seals and back up rings is vital to the function of the ABC system. I have seen many people posting on various forums about using o-rings from harbor freight which I would never recommend this. The seals that come in those multipacks are not the correct size and prone to premature failure and leaks.***

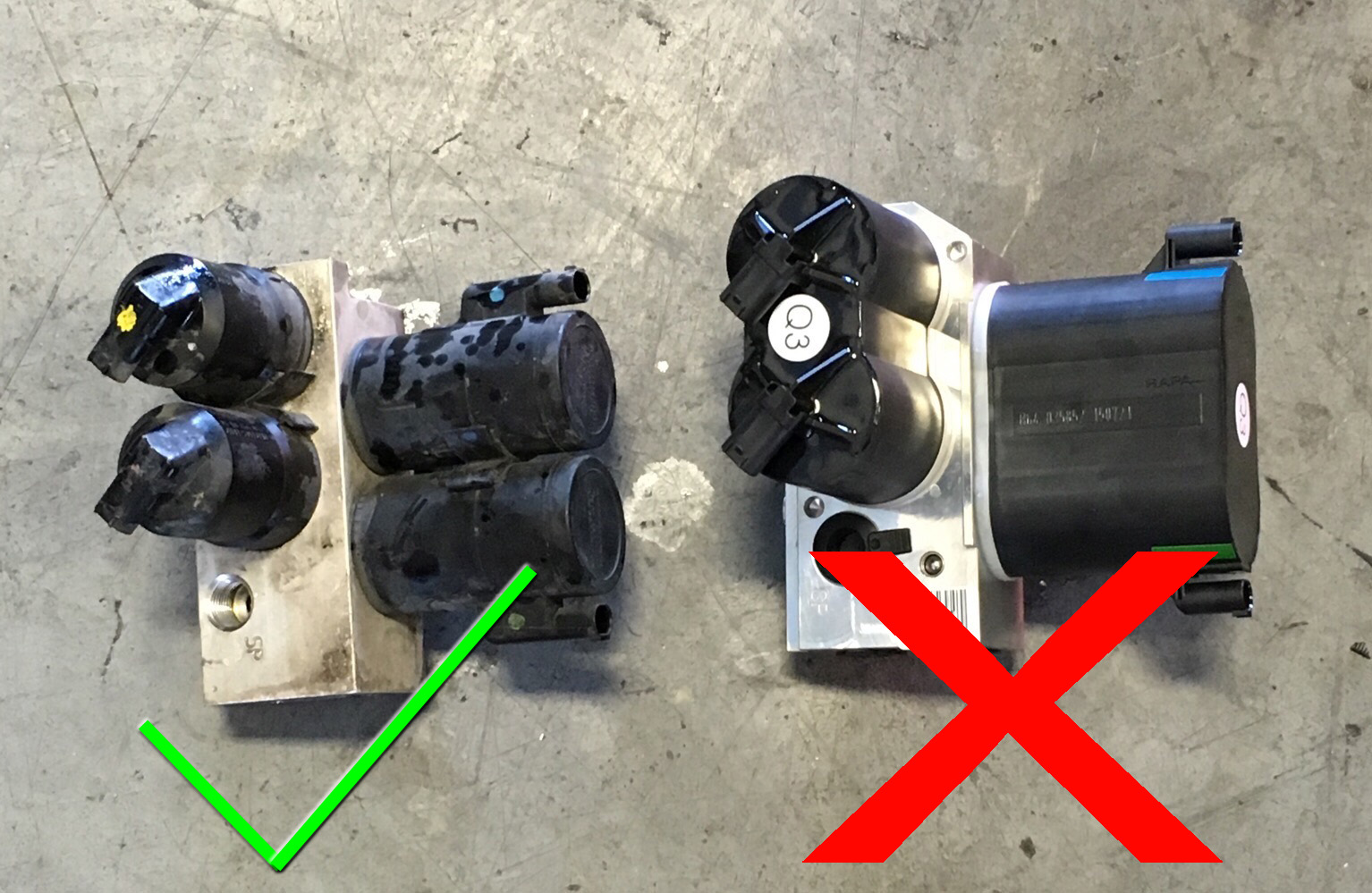

Two styles of valve blocks are found in these vehicles. In 2007 the design on the right became standard in all ABC vehicles along with a different design for the 221 and 216 chassis vehicles. These valve blocks are not serviceable and can not be repaired by replacing seals. The only available option is a thorough flush. The new style was also available as a replacement unit so if your valve blocks have ever been replaced it is highly likely you have the updated part on the right. The style on the left is the one that can be resealed and cleaned.

Around mid 2004-2005 the manufacture has switched from PTFE to Nitrile backup rings. The Nitrile backup rings have a shorter service life, deteriorate, and are more prone to extrusion damage sending little pieces of nitrile into the valves and throughout the system. PTFE backup rings are much more durable, installation is much easier, and the life span is much longer.

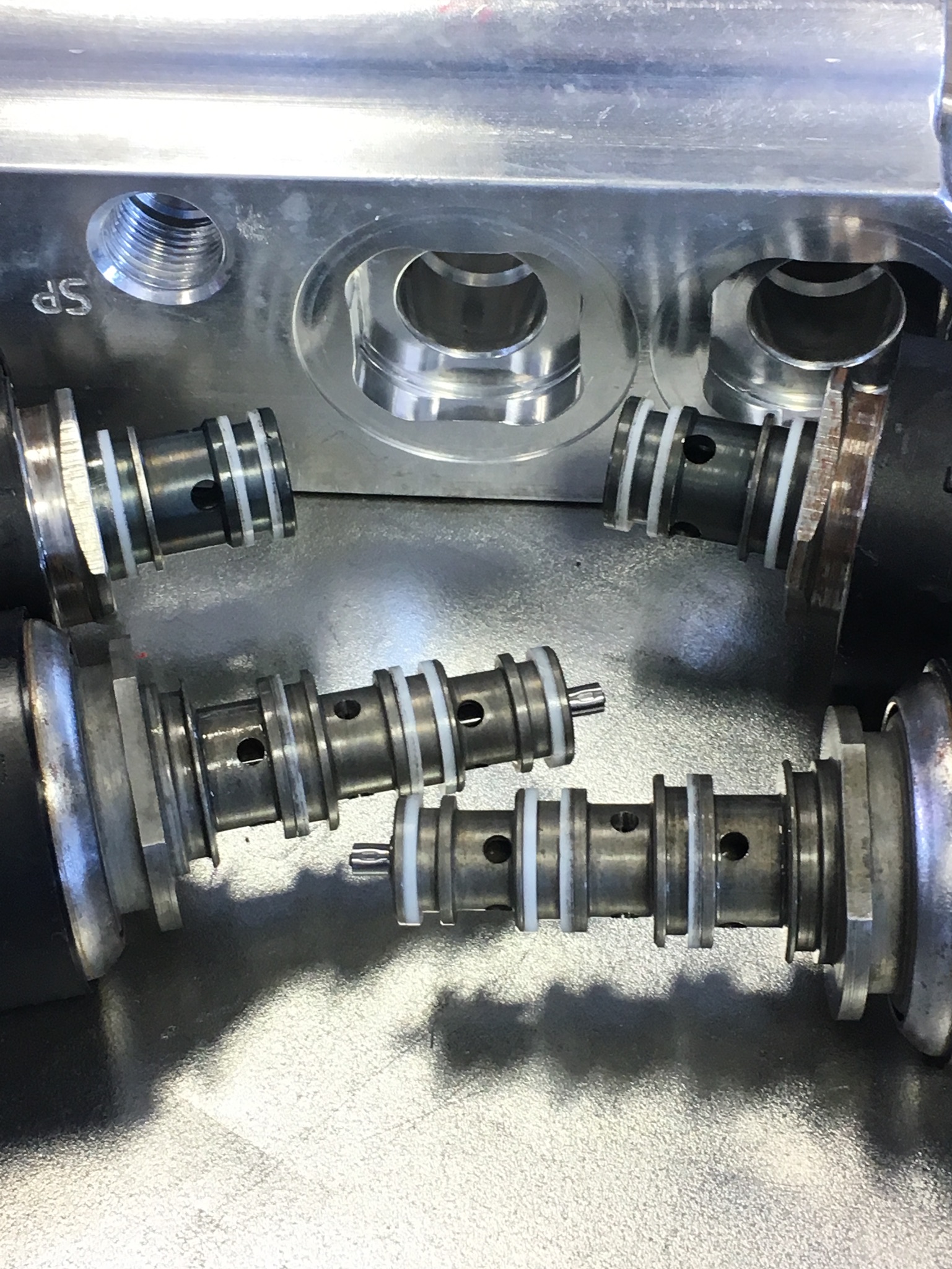

These are the valves with factory Nitrile backup rings. As you can clearly see on the bottom right hand locking valve the deterioration of the nitrile backup ring has started to allow pieces to break off and get caught in the valve seat. This type of wear does not occur with PTFE backup rings as they are a harder compound and have much higher resistance to extrusion.

These Images show extrusion damage to nitrile backup rings. All the material that comes off then travels throughout the system which is why a full flush is always required. Upgrading to PTFE is highly recommended, PTFE does not fail prematurely like this.

Doubling or tripling up on rings instead of using backup rings is never a good idea.

Cut away of control valve

Break down of a locking valve. For informational purposes only, do no disassemble your solenoids to this extent. Irreversible damage occurs removing plastic housing from the solenoid body as shown.

PTFE Backup Ring kit. This is our best selling kit. Comes complete with all o rings and PTFE backup rings. These are easy to install, last longer, and much more durable than the factory nitrile backup rings found on valve blocks mid 2004 and up. This kit will replace damaged PTFE rings on early valve blocks and is a great upgrade to the factory nitrile backup rings on the later valve blocks

THIS KIT IS BEING PHASED OUT - Limited stock remaining

Nitrile backup ring kit. Comes with all orings and Nitrile backup rings. Nitrile degrades at a faster rate than PTFE backup rings, they are more susceptible to extrusion damage. These are what the factory used from mid 2004 and up. If your valve block has nitrile backup rings you can upgrade to PTFE with our PTFE backup ring kit to avoid future issues.